Innovative technologies and features of G series air handling components

Advanced filter technology

The G series may use advanced filter technology, such as the application of multi-layer composite materials. These filter element structures may include a combination of various filter media, such as fiber materials, activated carbon, or ceramics, to provide stronger filtration capabilities. This design not only captures tiny particles and pollutants in the air more effectively, but also extends the service life of the filter element and reduces replacement frequency and maintenance costs.

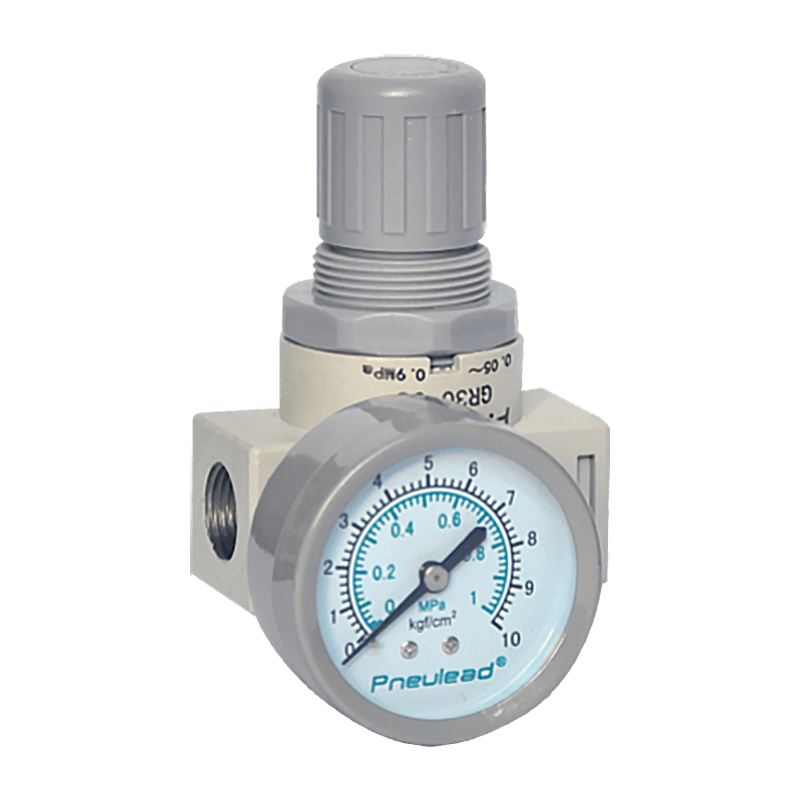

Precision pressure regulating mechanism

The regulator portion of this series may incorporate sophisticated sensors and control systems. By using advanced control algorithms and precision regulating valves, it can achieve more precise air pressure regulation and maintain the stability of the output gas. This precision pressure regulation mechanism ensures the reliability of the pneumatic system and reduces equipment failures and instability caused by air pressure fluctuations.

Intelligent lubrication system

In the G series, the lubricator may adopt an intelligent design, combining automatic control and quantitative oil supply functions. This intelligent lubrication system can automatically provide the appropriate amount of lubricant based on the working status and needs of pneumatic equipment. This not only improves equipment efficiency, but also reduces energy consumption and reduces lubricant waste.

sustainable design concept

The G Series may also focus on sustainability, using eco-friendly materials and energy-saving designs to reduce environmental impact. It is possible to use renewable materials to manufacture components and design energy-saving components, thereby reducing energy consumption during the production process and reducing waste generation, in line with the concept of sustainable development.

Advantages and benefits of G series air treatment components in industrial applications

G series air handling components demonstrate obvious advantages and benefits in various industrial applications. These

G Series Air Source Treatment Components can not only improve the purity and stability of industrial gases, but also bring many practical benefits to enterprises. For example, they can reduce equipment maintenance costs, reduce downtime, and increase productivity. At the same time, by effectively filtering and regulating gases, they ensure the consistency and stability of product quality, helping to enhance the competitiveness and reputation of enterprises.

These components can also bring sustainability advantages to companies. The use of advanced technology and design concepts can reduce energy consumption, reduce waste generation, and effectively control environmental impact during the production process to meet environmental protection requirements.

Customization and application range of G series air treatment components

G-Series air handling components may be highly customizable and can be custom designed based on customers' specific needs and industry standards. They are widely used in various fields such as automobile manufacturing, aerospace, food processing, pharmaceuticals, electronic equipment manufacturing, etc.

These industries have strict requirements on gas quality.

G Series Air Source Treatment Components can meet the special needs of different industries through their customized design and superior performance. For example, in the food processing industry, extremely high gas purity is required to ensure product safety and hygiene; in the aerospace field, extremely high requirements are placed on the stability and reliability of pneumatic systems.

EN

EN  English

English Español

Español