Electrical failure is one of the main reasons for air control valve control failure. In the application of electric control valves, motor failure, loss of control signal or abnormal power supply may cause the valve to fail to operate normally. The causes of motor failure are various, including overload, short circuit or motor aging, which will affect the output power of the motor and prevent the valve from opening and closing according to the predetermined angle. The lack of control signal may be caused by line failure, poor contact or interference signal inside the control system, which prevents the valve from receiving correct control instructions. Therefore, in order to reduce the risk of electrical failure, users should regularly check the connection, insulation condition and power supply status of the electrical system to ensure its stable operation.

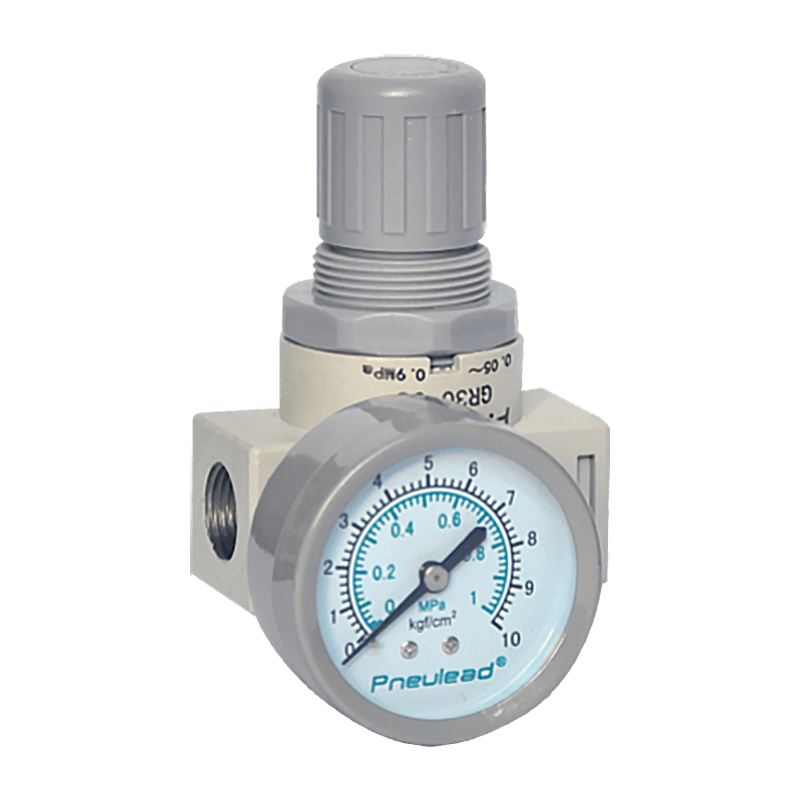

Pneumatic failure is also an important factor in air control valve control failure. In the operation of pneumatic control valves, insufficient air source, air pipe blockage or cylinder failure may affect the normal operation of the valve. Insufficient air source is usually caused by insufficient compressed air supply or failure of air source equipment, which will cause the valve to fail to obtain sufficient air pressure to perform the opening and closing action. Air pipe blockage may be caused by dirt, impurities or liquid accumulation in the pipeline, which will hinder the flow of gas and affect the working state of the valve. Cylinder failure is also a key factor. Wear or damage to the seal ring may cause gas leakage, which will affect the response speed and control accuracy of the valve. To ensure the normal operation of the pneumatic control valve, it is essential to maintain a stable supply of gas source, clean the air pipe regularly, and check the status of the cylinder.

Mechanical failure is also an important reason for the failure of air control valves. The mechanical parts inside the valve, such as the valve core, valve seat and connecting rod, may wear, deform or get stuck during long-term use. These problems will cause the valve to move inflexibly or even fail to open or close normally. When the gap between the valve core and the valve seat increases, the sealing performance will decrease, which may cause gas leakage and reduced control accuracy. The stuck phenomenon may be caused by insufficient lubrication, impurity accumulation or unreasonable valve design. Therefore, regular maintenance and servicing of the valve and checking the wear of the internal mechanical parts are important measures to ensure that mechanical failure does not affect the control performance.

Temperature and environmental factors may also cause control failure of air control valves. Air control valves usually operate within a specific temperature range. Too high or too low temperature may affect the performance of the valve material and the sealing effect. High temperature may cause valve materials to soften or deform, thereby reducing sealing performance; while low temperature may increase the brittleness of the material and cause valve parts to break. In addition, dust, moisture or corrosive gases in the external environment may also have an adverse effect on valve performance and cause control failure. Therefore, when designing and selecting air control valves, the temperature, humidity and other environmental factors of the working environment must be fully considered to ensure the reliability and stability of the valve.

EN

EN  English

English Español

Español